Socket machines are essential in various industries, particularly when joining plastic pipes. These machines, designed to deliver precision and reliability, have become indispensable for professionals working in plumbing, construction, and industrial projects. We’ll dive deep into socket machines, focusing on their role in plastic welding, their types, applications, and the numerous benefits they bring. Whether you’re a seasoned professional or just exploring your options, this guide will provide the clarity you need.

Understanding Socket Fusion Machines for Plastic Pipe Welding

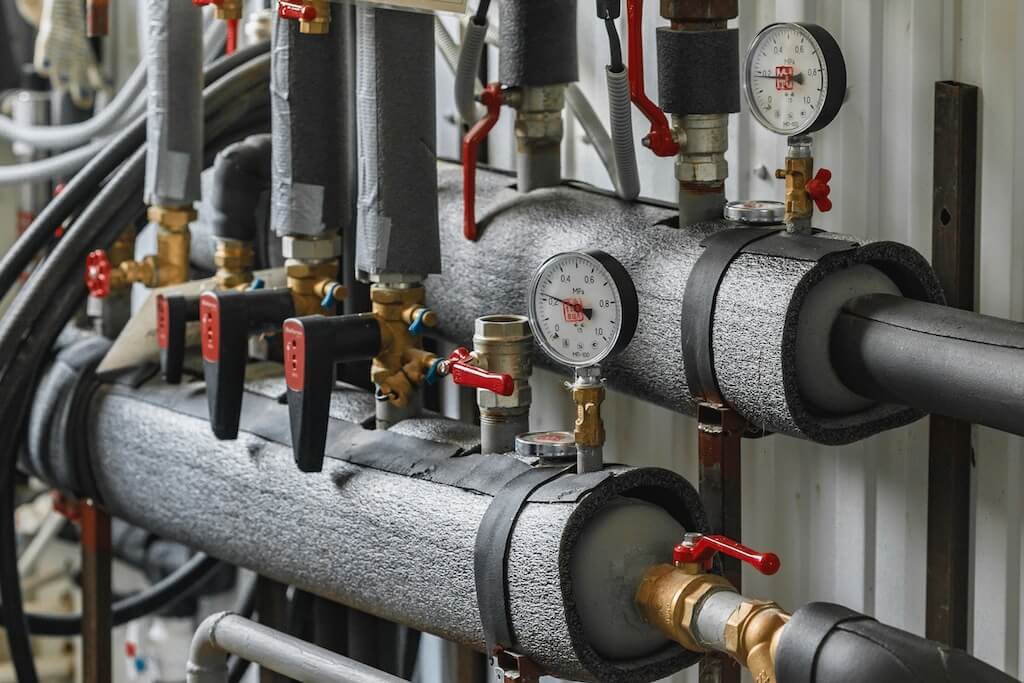

Socket fusion machines are a type of socket machine used to join thermoplastic pipes and fittings by applying heat and pressure. This process creates a seamless and durable bond that is resistant to leaks and wear. Understanding how these machines work and their practical applications can help you choose the right equipment.

What Are Socket Fusion Machines?

These machines are specialised tools used in the welding of plastic pipes. They work by heating the pipe, fitting it to a specific temperature, and softening the material before joining them. Once connected, the materials cool and fuse into a single, strong piece. This method ensures a reliable and leak-proof joint, making it a preferred choice in industries like plumbing, irrigation, and gas distribution.

These machines typically have interchangeable heating tools to accommodate various pipe sizes and are designed for easy operation, even in challenging environments.

Types of Socket Fusion Machines

There are several types of socket fusion machines available, each suited to different applications:

- Manual Socket Fusion Machines: These are compact and portable, ideal for small-scale projects or on-site repairs. They require manual operation, making them a cost-effective choice for smaller tasks.

- Semi-Automatic Socket Fusion Machines: Offering a balance between efficiency and affordability, these machines automate certain aspects of the welding process while still requiring some manual input.

- Fully Automatic Socket Fusion Machines: Designed for high-volume and precision applications, these machines handle the entire process, from heating to joining, with minimal operator intervention. They are often used in large-scale industrial projects.

- Customised Machines for Specific Materials: Some are tailored to work with specific types of plastics, ensuring optimal results for unique projects.

Applications of Socket Fusion Machines

They are widely used across various industries. Their versatility makes them an excellent choice for projects involving:

- Plumbing Systems: These machines create leak-free joints in residential and commercial water supply systems.

- Irrigation Networks: Farmers and landscapers construct durable and efficient irrigation systems using socket machines.

- Gas Distribution: The secure and seamless joints created by these machines are ideal for transporting gas safely.

- Industrial Piping Systems: Factories and manufacturing facilities use socket fusion machines to assemble robust, long-lasting piping networks.

Benefits of Socket Fusion Machines

Their popularity stems from their numerous advantages. Some key benefits include:

- Durable Joints: The fusion process creates a monolithic bond, eliminating weak points and ensuring long-term durability.

- Leak Resistance: Seamless connections reduce the risk of leaks, making these machines preferred for critical applications like gas and water distribution.

- Cost Efficiency: It reduces overall project costs by minimising the need for additional materials such as adhesives or mechanical joints.

- Ease of Use: Many models are designed for user-friendly operation, even for those with minimal training.

- Versatility: These machines can handle various pipe sizes and materials, making them suitable for diverse applications.

- Environmental Sustainability: The process generates minimal waste, contributing to eco-friendly practices in construction and plumbing.

Tips for Using Socket Fusion Machines Effectively

- Choose the Right Machine: Select a machine that matches the pipe size and material you’re working with.

- Follow Proper Heating Times: For optimal results, each material requires a specific heating duration. Refer to the manufacturer’s guidelines.

- Ensure Clean Surfaces: Clean the pipe and fit thoroughly before welding to avoid contamination and weak joints.

- Practice Safety: Use protective equipment and follow safety protocols to prevent accidents.

Ready to Enhance Your Projects?

If you want to elevate the quality and efficiency of your projects, investing in the right socket machines can make all the difference. These tools streamline the welding process and ensure lasting results.

At Agru Australia, we’re committed to providing high-quality solutions for all your piping needs. Our extensive range of products, including cutting-edge socket fusion machines, is designed to meet the demands of modern industries. Explore our offerings today and discover how we can help you succeed in your next project!