Infrastructure

Application Overview

AGRU is at the forefront of Infrastructure engineering, proving a range of product solutions to help solve complex challenges.

AGRU’s geosynthetic materials are found in civil structures around the world, from tunnels and water systems to dams and landfills. AGRU’s civil engineering solutions are designed to help control costs and speed up installation times while protecting existing structures or the surrounding environment. All geomembranes, geocomposites, geosynthetic clay liners, and other geosynthetic materials are manufactured in the U.S. and meet stringent quality control standards.

Multi-Purpose Solutions

Precast pipes

CONCRETE PROTECTION

AGRU-Ultra Grip protects concrete against corrosion and abrasion

Precast pipes and manholes for wastewater transport are often exposed to aggressive alkalis, acids and gases over years of operation. Without a lining, the castings will corrode and there is a risk of wastewater being released into the environment. AGRUSAFE concrete protective liners protect against moisture penetration, corrosion, abrasion, and leakages. This considerably extends the life of the castings. To ensure safe mechanical anchoring in concrete, the patented AGRU Ultra Grip anchoring stud is extruded in a single step with the concrete protective liner.

Drinking water

AGRULINE

Great operational reliability with e-socket fittings and elongated fittings

Above-ground and inground pipelines are a genuine challenge in terms of both engineering and planning. After all, water is a critical resource. The piping system must have the ultimate assurity. Welded joints and PE 100-RC ensure operational reliability. The stress crack-resistant polyethylene e-socket fittings are quick and safe to install using universal Electrofusion and Butt weld machines. With the WSSA product approval 1309 and Watermark on our range. Agruline products exceed National requirement.

Culverts

AGRULINE

Undercrossing with AGRU XXL pipes

Corrosion-resistant and stress crack-resistant PE 100-RC pipes are the best choice for installation as wastewater culverts. In this case, a new culvert line is crossing under the Spree river in Germany. To construct this large-scale, twin-pipe culvert under the Spree river, two large-diameter polyethylene pipelines of 1400 mm and 1200 mm were laid by horizontal directional drilling. Scratches and point loads cannot be completely avoided when the horizontal directional drilling method is used. Thanks to the use of what is currently the highest quality non-crosslinked material in accordance with PAS 1075, PE 100-RC, AGRU SURELINE pipes offer optimum protection against point loads, and the slow crack growth they cause, and against external damage

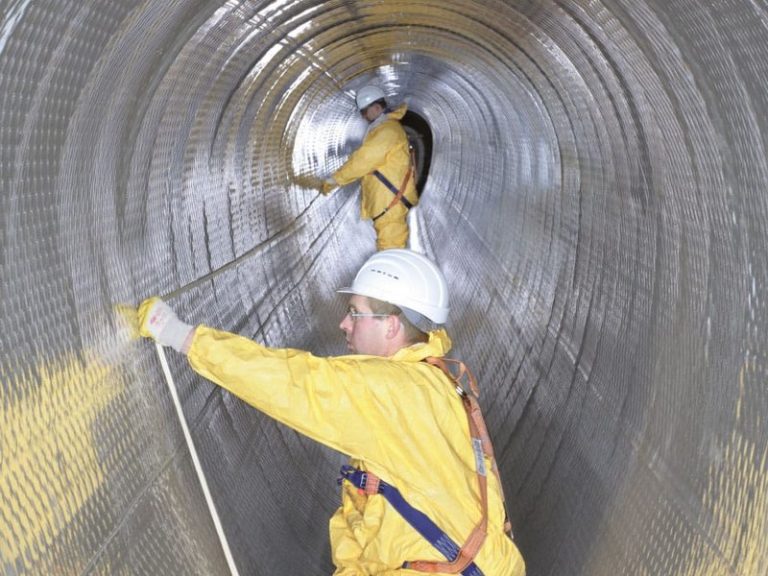

Relining

CONCRETE PROTECTION

Reconditioning with AGRU-Ultra Grip concrete protective liners

Concrete protective liners are used for pipe reconditioning and new installations in sewage tunnels. Concrete protective liners are used here to protect both concrete and reinforced concrete pipes against corrosion. The good mechanical properties of concrete and steel are combined with those of the thermoplastic material (PE, PP, PVDF and ECTFE). The result is a permanently sealed composite pipe that is resistant to corrosion, abrasion and chemical media. Various pipe cross-sectional shapes can easily be lined using our HDPE lining systems.

Water Storage

Structured Geomembranes

Integrated Drainage System can feature structured geomembranes such as AGRU’s Super Gripnet or MicroDrain Liner overlain with an AGRUTex geotextile. Simply place soil on top of the geotextile to complete the system. The greatest performing, and most versatile of the traditional methods, the IDS system can feature an aggressive texturing on the underside of the Super Gripnet geomembrane providing unmatched shear strength and stability even on steepened slope applications.

Precast pipes

CONCRETE PROTECTION

AGRU-Ultra Grip protects concrete against corrosion and abrasion

Precast pipes and manholes for wastewater transport are often exposed to aggressive alkalis, acids and gases over years of operation. Without a lining, the castings will corrode and there is a risk of wastewater being released into the environment. AGRUSAFE concrete protective liners protect against moisture penetration, corrosion, abrasion, and leakages. This considerably extends the life of the castings. To ensure safe mechanical anchoring in concrete, the patented AGRU Ultra Grip anchoring stud is extruded in a single step with the concrete protective liner.

Drinking water

AGRULINE

Great operational reliability with e-socket fittings and elongated fittings

Above-ground and inground pipelines are a genuine challenge in terms of both engineering and planning. After all, water is a critical resource. The piping system must have the ultimate assurity. Welded joints and PE 100-RC ensure operational reliability. The stress crack-resistant polyethylene e-socket fittings are quick and safe to install using universal Electrofusion and Butt weld machines. With the WSSA product approval 1309 and Watermark on our range. Agruline products exceed National requirement.

Culverts

AGRULINE

Undercrossing with AGRU XXL pipes

Corrosion-resistant and stress crack-resistant PE 100-RC pipes are the best choice for installation as wastewater culverts. In this case, a new culvert line is crossing under the Spree river in Germany. To construct this large-scale, twin-pipe culvert under the Spree river, two large-diameter polyethylene pipelines of 1400 mm and 1200 mm were laid by horizontal directional drilling. Scratches and point loads cannot be completely avoided when the horizontal directional drilling method is used. Thanks to the use of what is currently the highest quality non-crosslinked material in accordance with PAS 1075, PE 100-RC, AGRU SURELINE pipes offer optimum protection against point loads, and the slow crack growth they cause, and against external damage

Relining

CONCRETE PROTECTION

Reconditioning with AGRU-Ultra Grip concrete protective liners

Concrete protective liners are used for pipe reconditioning and new installations in sewage tunnels. Concrete protective liners are used here to protect both concrete and reinforced concrete pipes against corrosion. The good mechanical properties of concrete and steel are combined with those of the thermoplastic material (PE, PP, PVDF and ECTFE). The result is a permanently sealed composite pipe that is resistant to corrosion, abrasion and chemical media. Various pipe cross-sectional shapes can easily be lined using our HDPE lining systems.

Water Storage

Structured Geomembranes

Integrated Drainage System can feature structured geomembranes such as AGRU’s Super Gripnet or MicroDrain Liner overlain with an AGRUTex geotextile. Simply place soil on top of the geotextile to complete the system. The greatest performing, and most versatile of the traditional methods, the IDS system can feature an aggressive texturing on the underside of the Super Gripnet geomembrane providing unmatched shear strength and stability even on steepened slope applications.

AGRU provides plastics solutions for your specific application

We appreciate your interest. If you would like to learn more about our services or access additional information, please contact us!

Please support us with some short information about your project, so we can assign the AGRU expert that fits best with your needs.

Reach Out Now

Optimise Your Pipeline Systems with HDPE – Get Started Today!

Interested in learning more about how one of our products can make a difference in your next project?

Please reach out to us with your questions and one of our sales or technical staff will be happy to assist you.

We can help you determine your exact product or application-related needs. And because our products meet, and often exceed, industry standards you can rest assured knowing that you are getting the best solutions in the business.