Modern technology depends on extracting valuable elements such as lithium, magnesium, and cobalt from the ground. Precious metals such as gold, silver, and copper are equally as important. Whether operating an evaporation pond or heap-leaching ore, AGRU Australia has you covered.

AGRU geosynthetics are utilized throughout many mining operations, serving as the base liner system in tailings storage facilities (TSF), heap leach pads (HLP), ponds, and channels and for HLP, TSF, and waste rock closures. AGRU pipes, fittings, concrete protective liners, and other products can also help support more efficient mining operations.

AGRUCHEM

Explosion protection with PE-HD-el ESD and PPs-el ESD

Explosion protection is an important precautionary measure for the safety of people and systems. Potentially explosive gases and dusts can form in mining, the chemical industry, landfills, power plants, sewage treatment plants, gas supply industry, metal processing and coating, the pharmaceutical industry, and refineries. AGRU processes electrically conductive PE-HD-el ESD and PPs-el ESD with flame-retarding characteristics to create piping systems and semi-finished products. For safety reasons, products made of these materials are primarily used to transport highly flammable media, often replacing expensive stainless-steel pipes. Electrically conductive polypropylene and polyethylene offer the best protection against explosive atmospheres.

AGRUCHEM

Abrasion resistant MINELINE piping system.

Abrasive media such as tailings, slurry, and or kaolin/water mixtures often need to be conveyed in mining. MINELINE is a piping system specially developed and tested for conveying abrasive media. The multilayer pipe guarantees robustness and safety for extended service life and great economic efficiency. The unique abrasion-resistant layer is softer than the PE 100-RC core and is also present in the fittings, more than doubling the life of the pipe systems on many occasions – for a piping system without any weaknesses. On top of this, the white outer layer reflects sunlight, ensuring minimal thermal expansion and higher operating pressures in direct sunlight.

AGRUCHEM

Poly-Flo double containment piping system for twice the safety

Double containment piping systems are used wherever people or the environment need to be protected against hazardous media. Poly-Flo, a double containment pipe extruded from PP or PE, ensures maximum safety wherever aggressive media such as acids or alkalis need to be handled. The reliable Poly-Flo double containment piping system made of PPR or PE 100-RC is extruded in a single production step. Thanks to its compact design with a small annular gap and low weight, the system can be quickly and reliably installed using simultaneous welding, even in tight space.

AGRULINE

Surface and water table management with Sureline Piping system

To ensure accessibility to the raw materials water management is critical in Mining. Safe transport and storage of mining water is very important for environmental protection. The groundwater or mine water extracted here is transported from the opencut or underground mines to the mine water treatment plants and evaporation ponds. It can then be used as cooling water or process water in a power station or industrial operation. AGRU supplies crack-resistant pressure pipes made of polyethylene (PE-HD) in PE 100-RC with external diameters up to 3500 mm in the pressure classes SDR 7.4 to SDR 41 for this use case.

LINING SYSTEMS

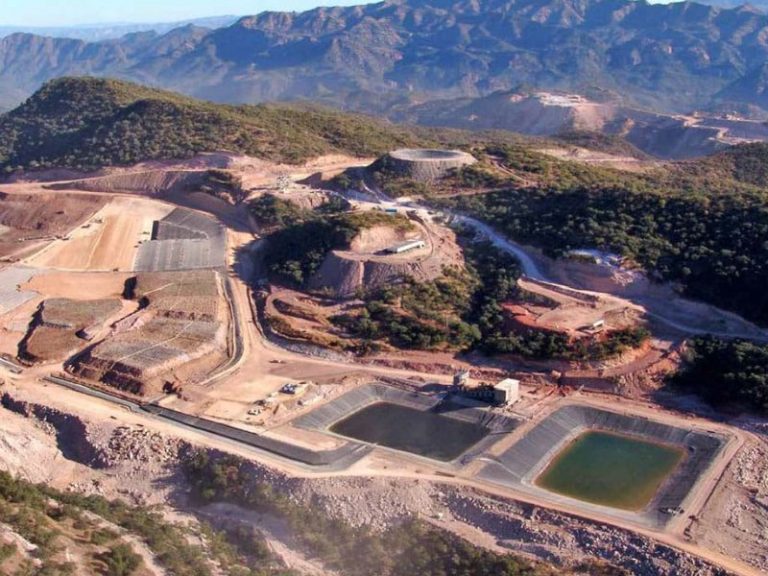

Groundwater protection with PE-HD LINING SYSTEMS

In mining, heap leaching is often used to extract gold, Copper, Nickel, Uranium, and other precious metals. To do this, the ore extracted from an open-cast mine is piled up on sealing sheets and sprinkled with Leaching solution. Gold for example which is finely distributed in the rock is soaked in a cyanide complex solution. The gold-enriched solution is collected in tanks and the gold is precipitated. To protect the groundwater against contamination, the best solution is to use high-quality PE-HD LINING SYSTEMS by AGRU. This thermoplastic seal provides long-term groundwater protection.

LINING SYSTEMS

Steep slope angles thanks to MIKROSPIKE High Grip

Mining by-products often need to be stored in tailing ponds and dams after the ore has been removed from the pit. These applications pose tough challenges in terms of the resistance of the material, as the geomembrane is in constant contact with the aggressive, concentrated media. The MIKROSPIKE High Grip geomembrane with more than 20,000 dimples/m2 is the product of choice for this special type of water reservoir.

We appreciate your interest. If you would like to learn more about our services or access additional information, please contact us!

Please support us with some short information about your project, so we can assign the AGRU expert that fits best with your needs.

Please reach out to us with your questions and one of our sales or technical staff will be happy to assist you.

We can help you determine your exact product or application-related needs. And because our products meet, and often exceed, industry standards you can rest assured knowing that you are getting the best solutions in the business.